R.A. Yancey not only supports jobs in this area, but we also serve many of the industries - food, beverage and healthcare - that are critical at this time. We were informed by the U.S. Department of Homeland Security and the Cybersecurity and Infrastructure Security Agency (CISA) that the lumberyard is an “essential business” due to our status as a critical supplier to the Food & Agriculture and Healthcare industries, among others. The lumberyard is one of the top three suppliers of clean pine chips that are used for production at WestRock, which produces packaging products for grocers, pharmacies, convenience stores, retail food providers, beverage, health and personal care supplies, and cleaning products and other household necessities. We also supply more than 300 poultry farms with shavings, and much of our production right now is being used for pallet production for food delivery across the Commonwealth.

Information Relating to Special Exceptions Request

In late January, the company submitted updates to Albemarle County regarding its special exceptions requests following the community feedback we received at the November Crozet Community Advisory Committee (CCAC) meeting. CCAC meetings are open to the public; however, we also invited our close neighbors to attend. We received many valid questions and concerns, which resulted in us taking a closer look at the specific requests. We have made comprehensive revisions to each request to scale back and only ask for modifications in the specific areas where needed.

The mill has been operating at this location since 1949. All of the current regulations that we are asking for modifications to were adopted in 1980, 31 years after the mill began operating. Because the mill existed before these regulations, the buildings and equipment that were in place prior to 1980 are legally exempt from these regulations. Therefore, they are legal and allowed to continue, even though they do not meet the current standards. What we’re trying to do now is request limited modifications to those standards so they reflect our long-standing mill operations. For this to happen, we need special exceptions.

There have been additions, as well as one new piece of equipment (sorter/stacker) that do not meet these current standards because they were not in place prior to the 1980 and subsequent regulations. The sorter/stacker, partially constructed in 2017, is a common piece of equipment used by most mills of our size. It is a multi-million dollar investment and essential if we want to remain competitive in our industry and ensure safer and more productive mill practices.

WHY ARE WE DOING THIS? In order for the mill to complete the sorter/stacker and remain competitive, we have to make sure all of the existing buildings, equipment and log and lumber storage areas on our property are compliant. To do this, we are asking for special exceptions to the 1980 regulations to allow the existing buildings, equipment and storage areas to remain in their current locations, many of which have been there for decades.

Below, we’ve highlighted the special requests that have received the most questions/comments from the community. To access the full plans, please click here.

Noise Exceptions:

First and foremost, we are not proposing to increase sound levels. We are asking that the regulations reflect the long-standing levels of our mill operations and legally accommodate these historic conditions. Sound levels will remain the same.

CURRENT STANDARDS: The max. 5-minute average source sound levels allowed in rural and residential zones are 60 dBA during the day and 55 dBA at night.

ORIGINAL REQUEST: We took the highest level measured on the property and asked for that decibel level, which was 80 dBA along Route 250 and 74 dBA along all other boundaries.

NEW REQUEST: We looked at areas that did not meet current requirements and tailored the revised requests to coincide more specifically to measured noise levels at each particular location.

Along Route 250 (points 15-19 in green): The typical or median 5-minute source sound level (the mill) shall not exceed 77 dBA after ambient noise is removed.

Note: Because ambient sound levels are so variant due to traffic, we measured sound levels over four hours rather than the county’s 5-minute requirement to determine the most typical sound levels. The typical total sound, including source sound (mill) and ambient noise (Route 250 traffic, for example), was 79 dBA. Typical ambient sound levels were 74 dBA. Removing typical ambient sound levels from typical total sound levels resulted in a typical source sound level of 77 dBA.

Adjacent to the New Sorter/Stacker (points 1-2 in pink): The typical or median 5-minute total sound level shall not exceed 70 dBA.

These numbers reflect the sorter/stacker being enclosed in two separate buildings with a wall in between to reflect noise away from the nearest property line. To comply with building code regulations, the large sorter/stacker building must be built as two separate structures, each open on one end, unless a sprinkler system is installed. Because of the possibility of a sprinkler system inflicting damage on the equipment and creating the risk of an electrical fire or employee electrocution, this is not a viable option. However, building two separate structures will impact noise-reduction efforts. As a result, the company is proposing two additional measures in an effort to avoid increasing the levels at this location: install noise-reduction materials on the inside of the sorter/stacker buildings, and build a wall in between the structures along the span of the gap (see example images below).

In order for the two enclosures and wall to be built, the special exception requests must be approved.

Picture of structures with gap.

Picture of wall spanning the gap.

Point 14 in Dark Blue: The typical or median 5-minute source sound level shall not exceed 66 dBA.

Points 12-13 in Orange: The typical or median 5-minute source sound level shall not exceed 64 dBA.

Point 10 in Teal: The typical or median 5-minute source sound level shall not exceed 72 dBA.

We want to reiterate that we are not requesting to increase sound levels. We are asking that the regulations reflect the long-standing levels of our mill operations and legally accommodate these historic conditions. Sound levels should remain at their current levels. Click HERE to read additional information about the county’s noise ordinance and our exemption requests, detailed in a memo by our sound consultant Bill Yoder with Acentech Inc.

2. Vibration Exceptions

As with noise, we are not proposing to increase any vibration levels. We are asking that the current regulations reflect the long-standing vibration levels of our mill operations and legally accommodate these historic conditions, which are not discernible by humans without specialized measuring equipment.

FOR CONTINUOUS VIBRATIONS: The mill meets all current standards except for the areas on the far side of Route 250 (points 16 and 18 in the image above), which are zoned as Village Residential and have a stringent standard of 0.00 in/sec in continuous vibration. It is impossible to measure 0.00 in/sec. According to our sound consultant, you cannot wave your hand in the air and receive a measurement of 0.00 in/sec. Traffic must be accounted for in this area, as well. We are proposing a new standard of 0.15 in this zone to match the non-residential zoning standard, which applies to all of the other measurement points along our property. The measurements taken at points 16 and 18 (on the far side of Route 250) were 0.0030 and 0.0018, well within the non-residential zoning standard of 0.15. To put this into perspective, this non-residential standard is half the threshold of vibration for even the most sensitive human ear.

FOR IMPULSIVE VIBRATIONS: We comply with standards at all locations.

3. Setback Regulations

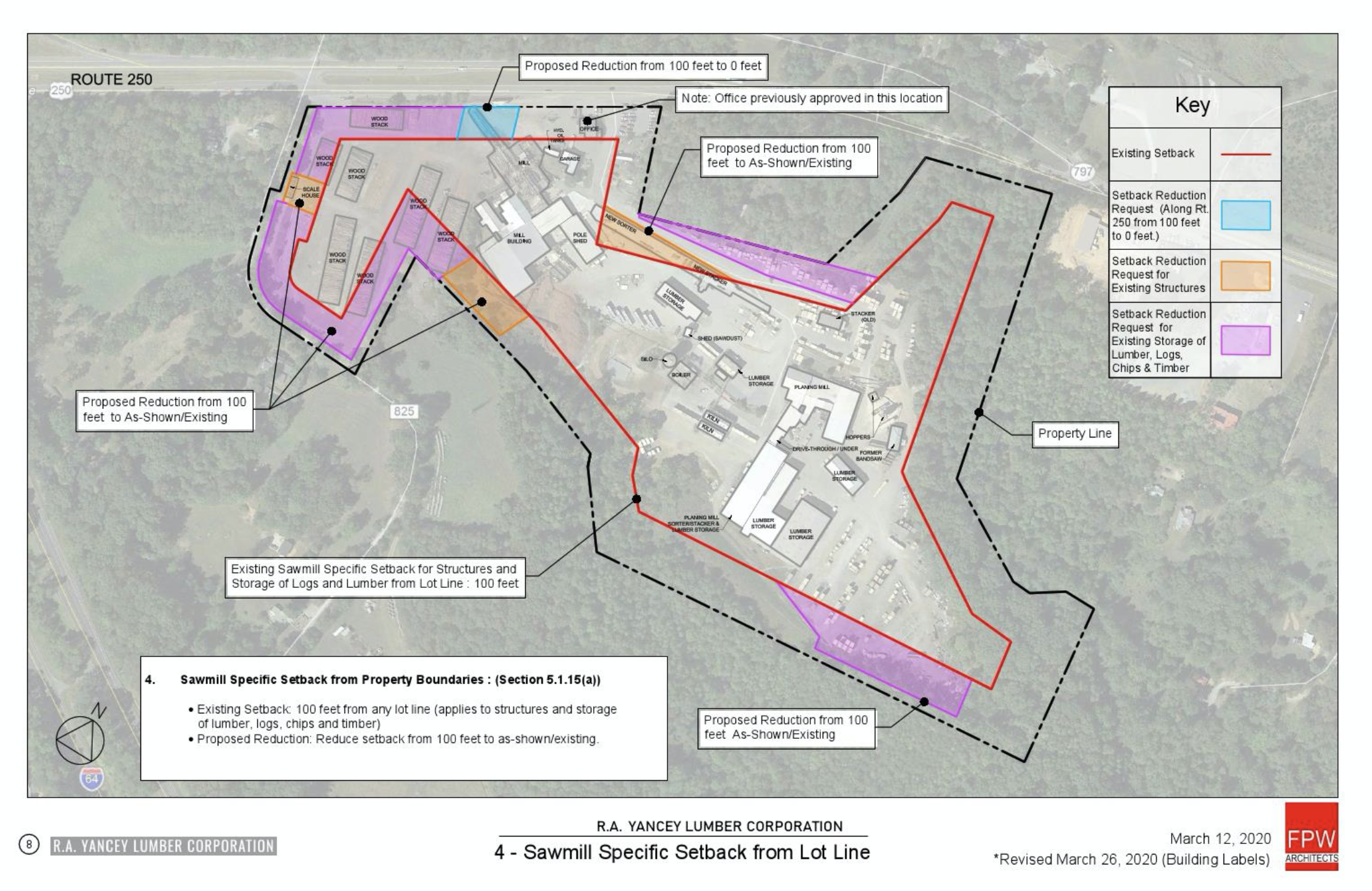

With regards to setback modifications, we are only asking for modifications to reflect the historic conditions of the mill’s operation and allow the buildings and log/lumber storage areas to remain in their current locations, and to permit use of the sorter/stacker in its current location. Based on feedback from the community, we have scaled back each request to reflect this; to only ask for modifications in the specific areas where needed.

For example, setback regulations for sawmills require all structures and log/lumber storage to be set back 100 feet from an adjacent residential or rural property line. In our original proposal presented at the CCAC meeting in November 2019, we proposed a reduction of the 100-ft building setback to 35 feet along the entire perimeter of our property. Based on feedback we received, we have dramatically reduced this request to only apply to specific locations on our property where existing buildings, the proposed sorter/stacker, and log/lumber storage do not meet the 100-ft setback as shown in the highlighted areas in the image above.

With the exception of the sorter/stacker (shown at the orange triangle at the top of the image), the other structures and log/lumber storage areas have been in place for decades. With regards to the sorter/stacker, some portions meet the 100-ft requirement. But, for the portions of the buildings that do not, we are proposing the setback line to align with the edge of the sorter/stacker buildings to ensure they could never be moved closer to the property line.

Additional setback regulations apply to sawmill equipment and require equipment to be located 600 feet from any off-site dwelling. (The 100-ft setback regulations referenced in the prior section apply to structures and log/lumber storage, not equipment.) Our original proposal was to replace this 600-ft equipment setback with a 35-ft setback along our entire property line. Based on feedback from the community, we have scaled back each request to reflect this; to only ask for modifications in the specific areas where there is an existing need. Our current proposal is to only ask for modifications to reflect the historic locations of the mill’s equipment and allow it to remain in current locations, as well as permit the use of the sorter/stacker in its current location (areas shown in yellow above).

Additional setback regulations apply to sawmill equipment and require equipment to be located 600 feet from any off-site dwelling. (The 100-ft setback regulations referenced in the prior section apply to structures and log/lumber storage, not equipment.) Our original proposal was to replace this 600-ft equipment setback with a 35-ft setback along our entire property line. Based on feedback from the community, we have scaled back this particular request like we have for the others; to only ask for modifications in the specific areas where needed. Regarding the requirement that sawmill equipment be set back 600-feet from off-site dwellings, our current proposal is to only ask for modifications to reflect the historic locations of the mill’s equipment and allow it to remain in current locations, as well as permit the use of the sorter/stacker in its current location (areas shown in yellow above). It is important to note that because the mill existed in its current location prior to the enactment of the 1980 restrictions, much of the existing equipment onsite was not subject to this regulation when it was adopted.

Fan Noise Issue Resolved

For nearly a year, we have been searching for a solution to a noise being produced by a boiler fan that heats our kilns. You can read our initial post about the noise here. We finally have some good news to share. This spring, we located an engineering firm in the U.K. that specializes in designing fan modifications to reduce tonal fan noise, which was the problem we were experiencing. The engineering firm designed a custom solution for our fan, which we have implemented to reduce the offending tone. After more than a week of testing this modification, we are confident we have found the solution.

Again, we apologize to our neighbors for the noise disruption and thank you for your patience as we worked to fix this.

New Fan Update

Since the new fan was installed, we have been measuring sound levels from the property line and at a neighboring home. When we ordered the fan, we were told the new fan would have a blade passage tone of 23 dB lower than the previous fan. It’s measuring just 7 dB lower. Obviously, this is another major disappointment.

We have since been in contact with the Director of Engineering at Twin City Fans (the fan manufacturer), as well as the fan rep, who has visited the mill and performed some additional testing.

At this point, we’re working on several additional solutions:

1. Reducing the wheel size in the fan housing: The fan manufacturer has evidence from another project showing that by doing this, it could reduce the sound level of the tone by up to 10dB. This would be an improvement, but it may not completely solve the problem.

2. Replacing the silencers. We are now working with four additional engineering and manufacturing firms regarding better-suited silencer designs. We are in the process of receiving conceptual designs and proposals from them and hope to have a final decision in the next few weeks.

Unfortunately, there is no simple solution to this problem. We will continue to keep the fan in pilot mode in the evenings and on weekends and run at a reduced level during the day until this issue is solved.

New Fan Testing

The new fan has been installed, along with the larger smokestack. We are currently monitoring noise levels while we operate the fan at various speeds and make adjustments to the equipment. We would appreciate any reports of noise be directed to info@rayanceylumber.com with your general location. We will have more information in the next few weeks. Again, we appreciate the patience of the community as we work to solve this problem.

Update

The cement has been poured and pipes have been designed for the new fan. We’re ready for the install once the fan arrives. We have not received any updates from the manufacturer; however, when the order was placed in mid-January, we were told to expect a minimum of 12 weeks for manufacturing and delivery. We are still operating on that timeline unless we hear otherwise.

We continue to operate the fan at a lower (quieter) RPM and in pilot-light mode in the evenings and on weekends.

A New Fan and Stack

After consulting with three different manufacturers, we’ve ordered a new custom fan that is being designed to produce significantly lower sound levels. This larger fan contains 20 blades (vs 8 blades on the current fan), runs at a slower RPM (1700 vs 2200), and its blades are specifically designed to reduce noise (backward curved vs radial blade). Along with the fan, we’ve ordered a new stack and all new pipes. We’re expecting the design and delivery to take 12 weeks, at a minimum. We will post updates as we receive them from the manufacturer.

We have been running slightly above pilot-light mode during the day and in complete pilot mode in the evenings since December 21. We will continue to operate at these levels until the new equipment is installed. As always, please feel free to email us at info@rayanceylumber.com with questions or concerns. Thank you.

New Muffler Update

After working with engineers and having a second muffler custom designed and expedited, we are sorry to report the second muffler has failed to solve the issue. This obviously is not the situation we were hoping for. We apologize to the members of the community who have been affected by the noise for the past four months. Please understand that we want this resolved as quickly as possible, as well. Our company has been a part of this community since 1949. We are committed to being a good neighbor. We wish there was a quick and easy fix to the noise.

We have located a manufacturer who is willing to design an alternate fan, which we are told will produce much lower sound levels. A new fan will most likely result in the need for a larger smokestack. We are waiting to hear how long this will take. We have asked that the fan be expedited at our expense.

Again, we apologize for the disturbances our operations have caused. We will continue operating the fan in pilot-light mode in the evenings until a solution is determined. We will operate in pilot-light mode completely on Dec. 24-25 with the hopes that everyone can have a peaceful holiday.

Testing New Muffler

We are testing the new muffler tonight. Please email us at info@rayanceylumber.com with your general location if you hear the noise. Any descriptions of the noise you can provide would be helpful, as well. Thank you.

New Muffler Arrived

The new muffler has arrived. Our team is working to build the frame and install it. There may be some noise as we test it to ensure everything is installed correctly. Please email us at info@rayanceylumber.com with your general location if the noise becomes bothersome. Thank you.